Our Impact

Innovation

Laundry isn’t part of what we do, it’s everything we do.

Our culture of innovation guides how our teams at Alliance Laundry Systems invest in R&D, how engineers test and refine our products and how we collaborate with customers to solve real-world laundry challenges.

As the needs of individuals and businesses evolve—from busy families to hospitals, hotels and first responders—so does our commitment to innovate. This singular focus powers the advancements that keep us leading the industry forward, one meaningful breakthrough at a time.

What We Do

Our Approach to Innovation

Our innovation journey starts and ends with the people and communities we serve. Each of their distinctive needs shape our product research and drive our development roadmaps. Their pain points guide our problem-solving.

We focus where it matters most:

- Customer Value: Every innovation is about delivering ROI and solving real challenges.

- Focus and Speed: We don’t chase trends. We prioritize purpose-built solutions that can be delivered quickly and cost-effectively.

- People-powered Thinking: Our customers, employees and engineers are at the center of everything we do.

- Process-driven Results: A defined innovation framework helps us remove roadblocks and build momentum, from idea to launch.

Our Innovation in Action

Our innovative technologies are designed to be real, relevant and measurable. A key example is ProCapture™, our lint-capture system.

Developed in response to direct customer feedback, ProCapture solves one of laundry’s most stubborn challenges: Excessive lint. Leveraging cyclone technology to capture lint by up to 98%, ProCapture extends machine life, lessening maintenance needs and improving air quality in laundry environments. It’s a smarter, more sustainable way to manage a costly problem.

But ProCapture is just one example among many. From lowering energy use to integrating AI in product development and mechanical optimization, we’re reimagining what laundry can do—and how we do it.

How We Do It

R&D Investments

Since 2020, we’ve devoted $100 million+ to research and development. That investment supports a growing portfolio of laundry-focused technologies aimed at improving laundry equipment performance, reducing energy consumption, enhancing sustainability and improving our users’ experiences. It’s all part of our goal to deliver dependable, high-performance solutions for commercial laundry professionals and residential users alike.

Strategic Partnerships

We believe collaboration is a catalyst for generating ideas. That’s why we partner with everyone from Fortune 500 companies to emerging startups—building big ideas with practical expertise to move laundry forward. These partnerships enable us to advance technologies like cloud connectivity, AI-driven development and data-informed optimization strategies that improve laundry performance and efficiency.

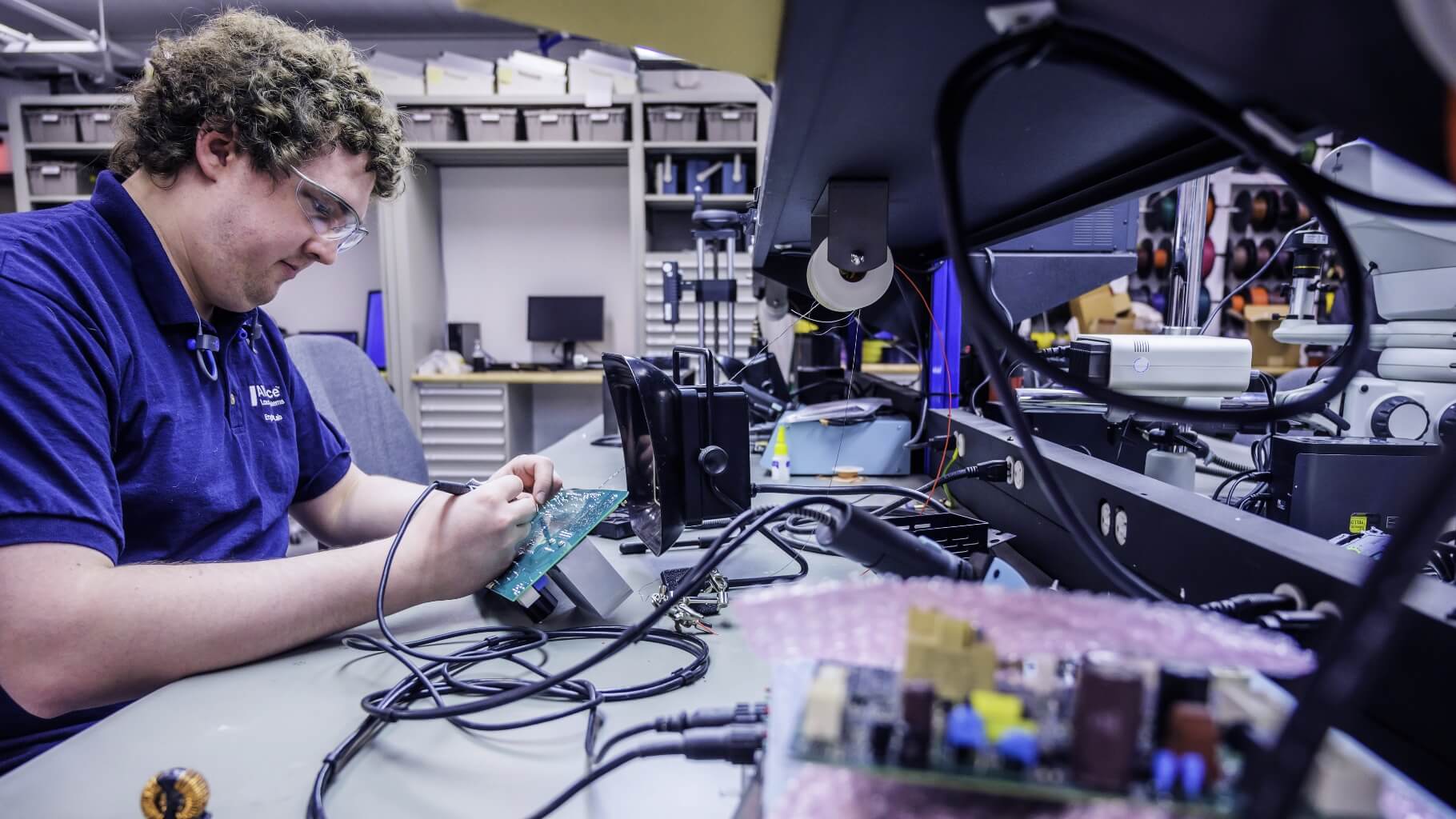

Many collaborations take shape within ALS TechLabs, our hub for software integration, mechanical exploration, and real-time product testing. It’s where imagination and execution meet—and where strategic partnerships help transform concepts into cutting-edge laundry solutions.

Our Labs and Test Centers

From Ripon, Wisconsin, to Pribor, Czech Republic, our global test labs and training centers are where big ideas meet real-world performance. These facilities enable us to simulate extreme conditions, test machine durability, and make fast, informed improvements using live data. With 24/7 testing capabilities, we’re always pushing limits to validate and accelerate innovation.

Our 6-Step Process

1

Ideation

Ideas come from everywhere—customer insights, employee suggestions, and industry trends.

2

Scoping

We assess feasibility and business value to ensure we’re solving the right problems.

3

Proof of Concept

All potential solutions are tested to determine the best path forward.

4

Engineering & Development

Designs are refined with advanced tools, including AI-driven modeling and mechanical simulations.

5

Testing & Validation

From internal testing to global certifications, we ensure every machine performs flawlessly in the field.

6

Manufacturing & Launch

Once proven, we bring innovations to market with efficiency and scale.

Bringing New Ideas to Life

Our internal idea portal empowers team members to submit feedback they’ve gathered directly from end customers, ensuring that real-world needs drive our innovation efforts. And we even operate our own laundromats to test machines in real-world settings—because living the customer experience helps us design smarter for it, too.

Built for Laundry. Built for Life.

We’ve dedicated our company to one thing—laundry. And that singular focus gives us a competitive edge. We understand the demands of laundry like no one else, and we’re committed to transforming every part of the process for the betterment of our customers and the communities in which they live.